MAIN TOPIC

Gas production and gas storage

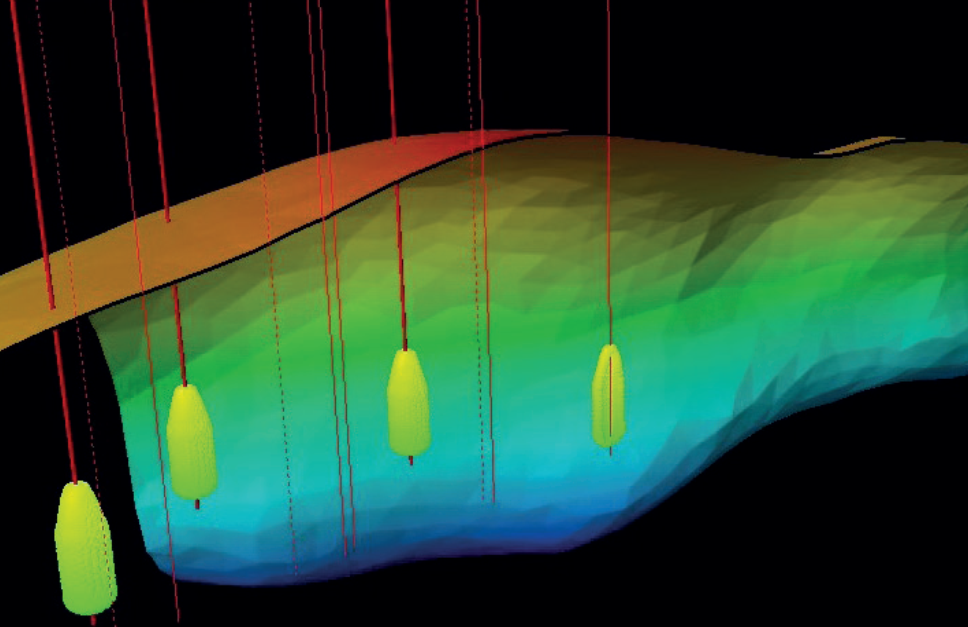

Our services include the construction, operation, and decommissioning of underground storage facilities (UGS) as well as the exploration, development, and enhancing recovery of gas and oil reservoirs.

Comprehensive services from a single source

- Planning, design, tendering, construction, commissioning, and operational support of UGS in depleted gas and oil reservoirs, aquifers, caverns, and oil/gas fields

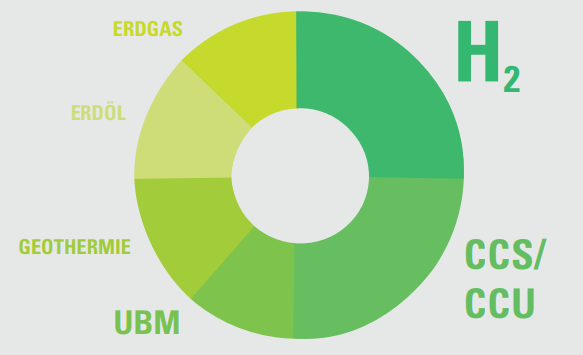

- Geological exploration and creation of reservoir models including laboratory analyses of geological, petrophysical, and reservoir properties

- Field development

- Site supervision

- Support with procurement procedures

- Monitoring and operation optimization

Underground gas storage

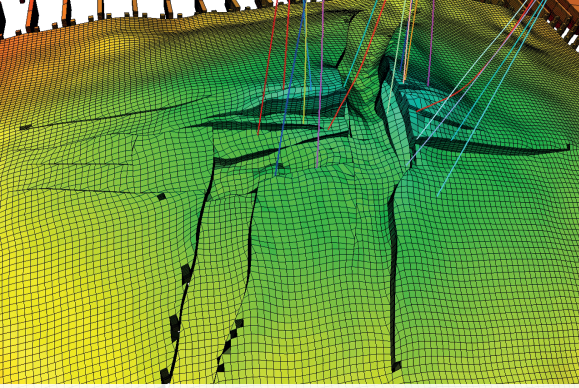

We provide engineering services for the construction and optimization of cavern and pore storage facilities.

- Determination of effective storage pressures

- Determination of storage capacities for various storage media such as natural gas, hydrogen, carbon dioxide

- Cap rock integrity assessment of including laboratory testing

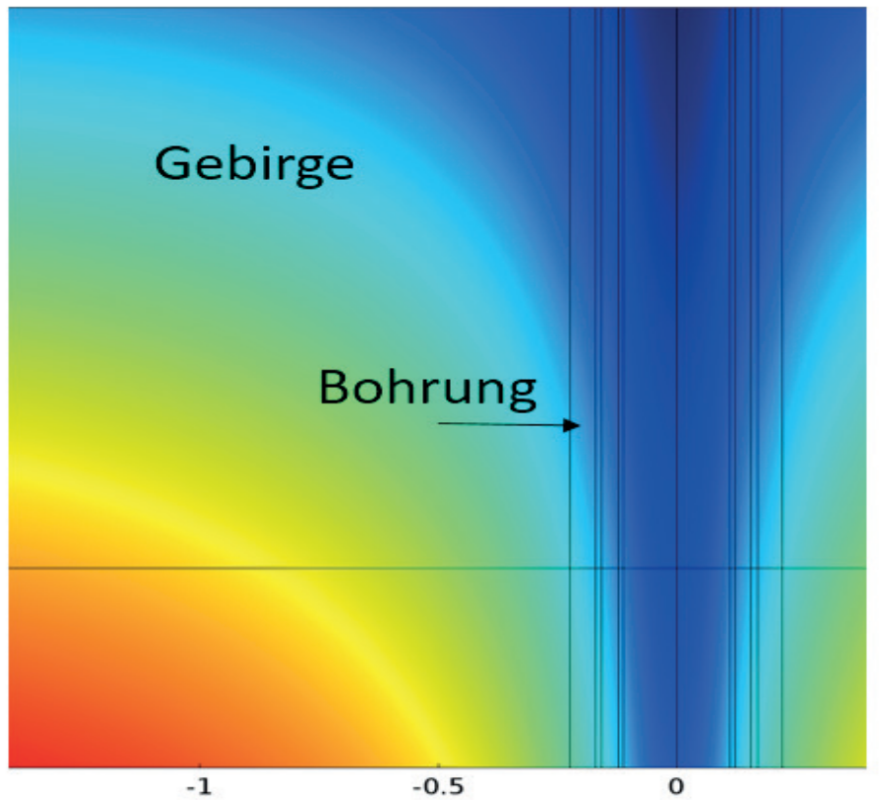

- Analysis and modeling of flow processes in the reservoir

- Storage operation optimization , water production control

- Design and monitoring of brine and initial gas filling

- Design, supervision and evaluation of leak tests

- Storage decommissioning with maximum working gas volume (WGV) and cushion gas volume (CGV) withdrawal and planning for subsequent utilisation of storage

Gas and oil deposits

We provide services ranging from exploring new deposits to enhancing efficiency in mature fields:

- Evaluation of geological and geophysical exploration data

- Evaluation of well tests

- Laboratory investigations on petrophysics and fluid properties

- Complex 3D geo-modeling and reservoir simulation

- Enhanced recovery for oil and gas

Wellbore integrity

- Design

- Material selection

- Mechanical-hydraulic-thermal stress analysis

- Decommissioning technologies

Well completion

Connection of the reservoir to the borehole

- “Open hole” and “cased hole” completion

- Well inclination and trajectory

- Sand control and requirements

- Simulation of injection and production performance of well completion

- Production optimization (single or multiple zones)

Production completion

- Artificial lift methods (gas lift, submersible centrifugal pump (ESP), etc.)

- Single and dual completion

- Tubing isolation (packer or equivalent)

- Annular production and injection

- Optimization of tube sizes

- Wellhead equipments

Analysis of well tests

- Interpretation of wellbore pressure

- Productivity and injectivity tests

- Evaluation of the reservoir parameters

Your contact to us

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.